Sites & Travel

Less travel, and more energy efficient offices and factories, will contribute to emission reductions.

Sustainability

Less travel, and more energy efficient offices and factories, will contribute to emission reductions.

Scope 1 and 2 emissions

Our ambition is to achieve net-zero emissions in all of our sites and offices by 2030. To achieve this, we are deeply committed to minimizing scope 1 and 2 emissions, targeting a reduction of 90-95% through focused initiatives.

We will also procure high-quality carbon removal credits to offset any residual emissions. Our preference lies with Direct Air Capture (DAC) projects, as recommended by the globally recognized Science-Based Target initiative.

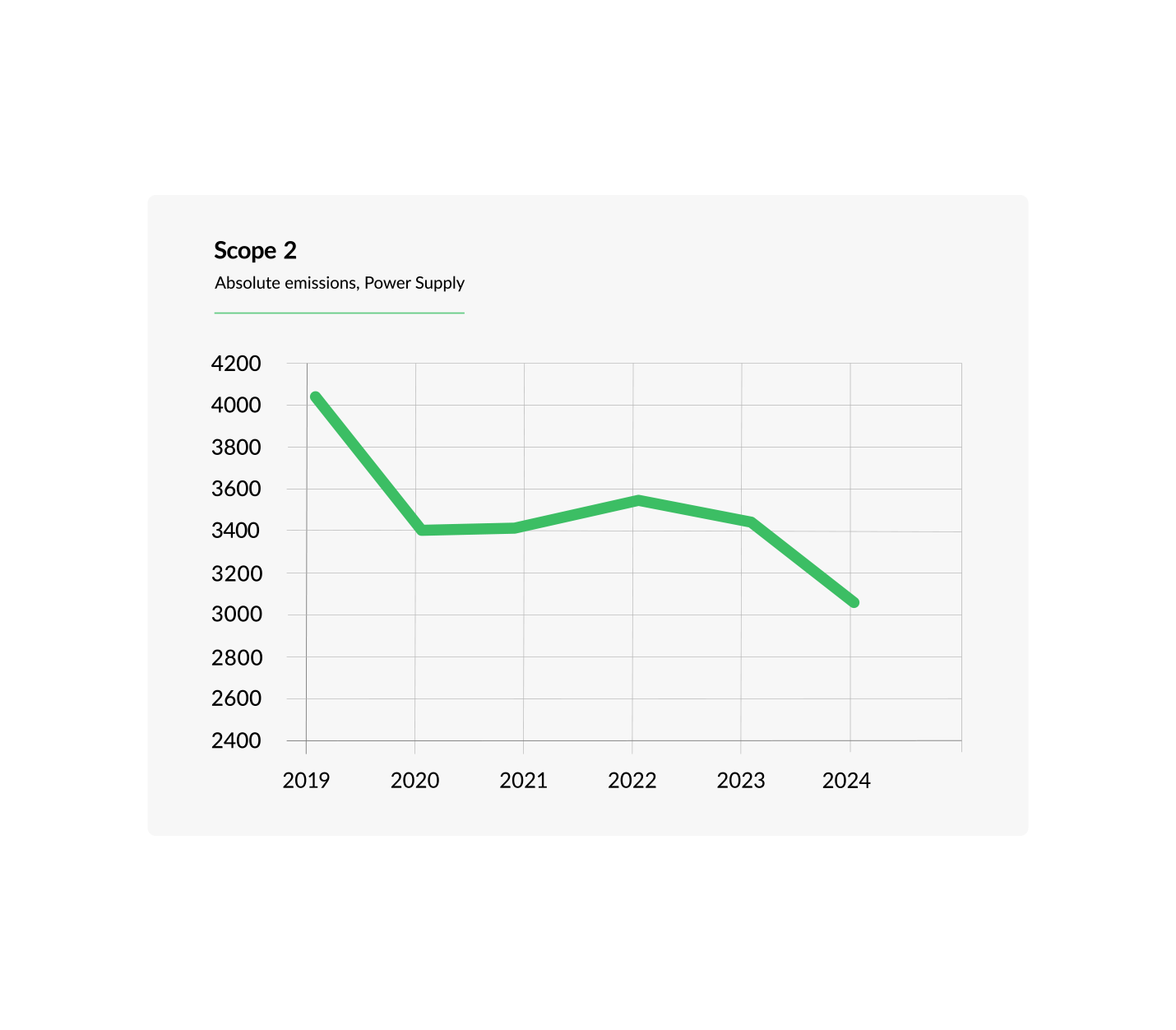

We are committed to reducing electricity consumption and increasing the use of green energy, like solar energy, at our Gatesville and Monterrey manufacturing sites. From 2019 to 2024, total energy consumption for our operations has dropped by 25%.

From 2023 to 2024, the absolute reduction in power supply was an 11% decrease.

STORY

Our Gatesville and Monterrey factories are making strides toward becoming net zero sites. Solar panels on their roofs deliver 45% and 29% of the electricity supply, respectively. Projects to increase energy efficiency, such as LED lights and updated machinery, saved 130,000 kWh annually, equivalent to 92 tons of CO2 emissions.

Gatesville aims to increase solar supply to 90% by Q1 2023 and become net zero on non-renewable electricity by end-2023. This will reduce CO2 emissions by an additional 1,536 tons per year.

Monterrey plans to shift to less energy-intensive manufacturing techniques.

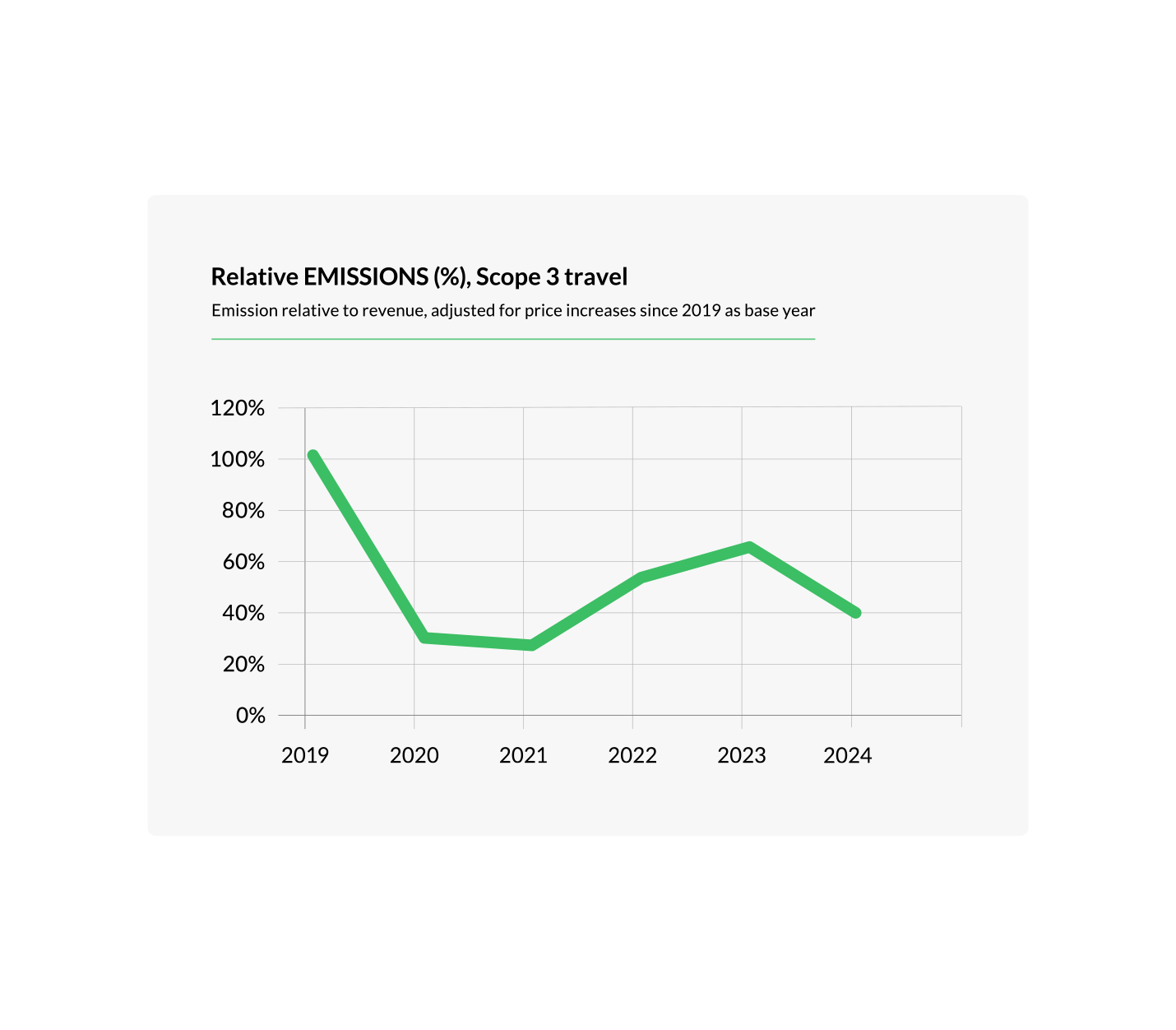

Although emissions from travel only make up 3% (2,000 tons of CO2e) of our overall emissions, they are a crucial area where we can realize increased efficiency and cost savings. Our focus on good practices has led to a reduction in emissions. However, the pandemic has further underscored the importance of transitioning to virtual communication, both internally and with our customers and partners.

While physical gatherings remain valuable, most of our communication now takes place online. We aim to conduct at least 80% of our services virtually by 203, with the potential to reduce emissions by 8 to 5 thousand tons of CO2e.

Travel-related emissions represented 21% of total emissions in 2019; in 2023, it was down to 16%. In 2024, it was further reduced and today accounts for 11% of total emissions.

In relative numbers, we see a significant reduction in emissions from 2019 to 2020 and 2021. This is due to extraordinarily low emissions from travel due to the COVID pandemic. As the model shows, the reduction in 2024 indicates a 39% reduction compared to 2023 and 52% compared to 2019.